Compact and Fanless Design Ensures Quick Implementation without Shutdowns or Infrastructure Upgrades

— Peter Yang, President

FREMONT, CA, USA, October 3, 2022 /EINPresswire.com/ — NEXCOM, a leading global supplier of network appliances, announced today launch of the NEXCOM ISA 140, a next-generation security solution to support industrial security appliances that is designed to meet the unique challenges of operational technology (OT) security.

“Cybersecurity is of the highest priorities for businesses today, but while IT security has improved, the operational technology used to monitor and control industrial processes has not received as much attention,” said Peter Yang, President of NEXCOM. “As digital transformation efforts accelerate within the manufacturing industry, this problem will only get worse, making Industry 4.0 a target for cybercriminals.”

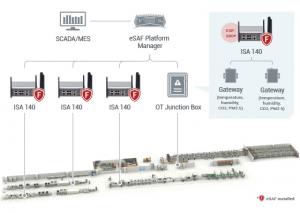

NEXCOM’s industry-specific solution, the ISA 140 for industrial security applications, is used for micro-segmentation and packet inspection on an OT network. The ISA 140 is powered by Intel’s latest dual-code Atom processor. Its compact, fanless design makes it simple to install, without causing costly plant shutdowns or extensive infrastructure upgrades. Once the ISA 140 is in place, its innovative out-of-band (OOB) remote management feature and bypass functionality allow OT security personnel to maintain the devices without disrupting the network.

One of the key additions digital transformation has brought to modern factories is the implementation of IoT technology. This includes data collection sensors that provide real time monitoring and data analysis of manufacturing processes. IoT technology is helping the industry collect and utilize data from traditionally unintelligent manufacturing assets to improve reporting, scheduling and maintenance, process optimization, and more.

“While the benefits of merging IT and OT resources is obvious, the convergence also brings significant cybersecurity risk,” said Peter Yang. “A smart factory is working in real time, exposing its OT networks to attack and the manufacturer to real time operational risk. OT has historically been difficult to protect, because legacy equipment cannot be easily equipped with security software, and partnering with OT vendors on cyber security brings with it another layer of risk.”

The biggest factor in OT security risk to date has been the technical limitations of OT endpoints, legacy systems that are not designed with cyber security best practices in mind. Many manufacturers also run on proprietary operating systems, making it impossible to install new security software solutions designed to repel the latest threats. However, any device with network connectivity could become a potential entry point for a cyber-attack, and must be protected.

A white paper is available.

Features

• Intel Atom x6212RE (Elkhart Lake) industrial grade processor

• Up to 16GB memory

• 1 GbE x 6 w/ 1 bypass pair, 1 port OOB support

• SMA antenna x 4

• Internal interface

o M.2 2242 key B slot x 1

o M.2 3042 key B slot x 1

o Minicard full size slot x 1

o Micro SIM slot x 1

• Operating temperature -30⁰C – 70⁰C

• Fanless design

To learn more, please visit the NEXCOM website.

About NEXCOM

Founded in 1992, NEXCOM integrates its capabilities and operates eight global businesses, which are Industrial Mesh, Intelligent Platform @ Smart City, Intelligent Video Security, Mobile Computing Solutions, Medical and Healthcare Informatics, Network and Communication Solutions, Smart Manufacturing, and Open Robotics and Machinery. This strategic deployment enables NEXCOM to offer time-to-market, time-to-solution products and services without compromising cost.

Peter Yang

NEXCOM

+1 5103862266

peteryang@nexcom.com

![]()